How Do I Design A Frame?

There are many considerations that go into designing a frame, far more than can be answered here. First, of course, is the rider: a custom frame will be designed around your particular leg length, torso length, arm length, and preferred riding position.

Then there is the intended use of the bike: do you want a fast-handling crit bike, or a loaded touring bike that handles smoothly descending the Alps with 50 lbs. of gear? What diameter of wheels and width of tires do you want to use? Do you need fender clearance? What size are your shoes? (Seriously: shoe size affects toe clip clearance in front and chainstay and pannier clearances in back. If you will be touring in mountain bike shoes or even boots, you may need more room than if you stick to sleek road riding shoes.)

For an amateur, a great introduction to the design and construction of a lugged steel bicycle frame is Lugged Bicycle Frame Construction, A Manual for the First Time Builder: Expanded Second Edition, by Marc-Andre Chimonas. This is an excellent introduction from an amateur builder who decided to share his experience in a self-published book. The book combines straightforward instruction with the author's personal opinions on frame issues. Take the opinions with a grain of salt, but the directions will step you through the process clearly.

Another excellent guide is now out of print, Richard Talbot's aptly named Designing and Building Your Own Frameset: An Illustrated Guide for the Amateur Bicycle Builder published by the Manet Guild. Talbot discusses both theory and practice of building a lugged steel road frame, including building your own jigs. The emphasis is on hand labor, not machine tools -- he assumes you will miter your tube joints by hand with files and scrapers, not stick the tubes in a milling machine. There's an introduction to brazing and materials, too, though it's specifically *not* a beginner's guide to brazing -- Talbot suggests looking for a local vocational school to learn how to braze, since practice is essential. The design considerations apply no matter what construction method you plan to use, so this is still a useful book for the welders out there.

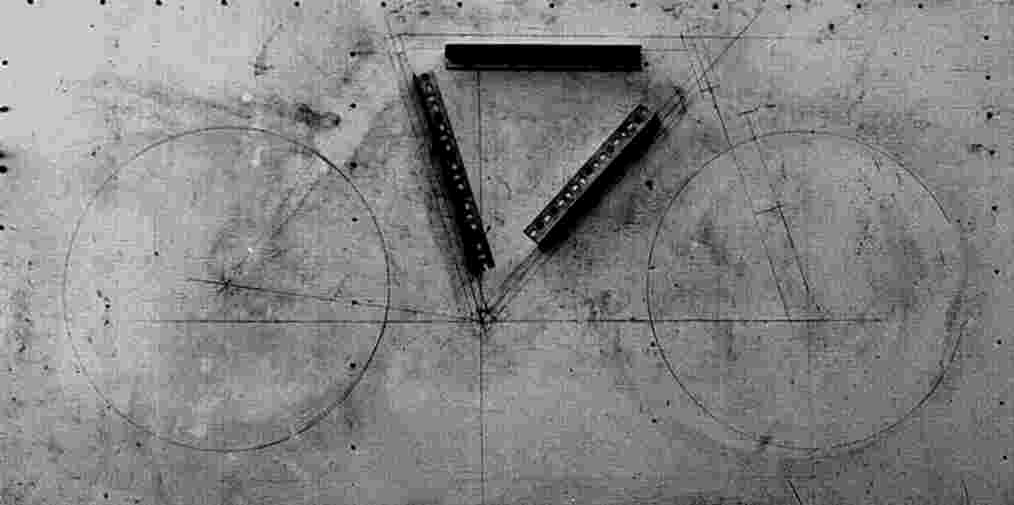

Here's a picture of a very simple frame jig

made from plywood and angle iron, similar to what Talbot describes. I

drew the frame design full-scale on a sheet of plywood, cut out gaps

for brazing joints, and shimmed angle iron out from the surface to get

the tubes into the same plane. This is what I built my first frame on,

and it came out within a millimeter of perfectly aligned. Fancy

production jigs make changing the jig setup quick and easy, but they

really aren't needed for do-it-yourself scale production.

Here's a picture of a very simple frame jig

made from plywood and angle iron, similar to what Talbot describes. I

drew the frame design full-scale on a sheet of plywood, cut out gaps

for brazing joints, and shimmed angle iron out from the surface to get

the tubes into the same plane. This is what I built my first frame on,

and it came out within a millimeter of perfectly aligned. Fancy

production jigs make changing the jig setup quick and easy, but they

really aren't needed for do-it-yourself scale production.

Henry James Bicycles, Inc. Henry James is a n excellent source for books, tools, supplies, and frame building parts. . His main business is making and selling beautiful cast lugs, fork crowns, and bottom brackets in both CrMo and stainless steel. He also stocks brazing supplies, his own beautiful, well-thought-out frame and fork jigs, and Tim Paterek's two-part video on fillet brazing. If you're seriously interested in building more than one bike, order Paterek's book from Henry James and ask for a price list, too.

Other Good References on Frame Design and Bike Fit

While Talbot and Paterek both tell you how to design a frame, there are many ways of sizing a frame to fit a particular person, and no one way can be taken as gospel. The following are good references for bike fit, though most do not directly address actually designing a frame.

- Bicycling Science by Whitt & Wilson isn't a design manual, but rather a good summary of much of the science behind the design and operation of bicycles. It has extensive discussions of steering and handling, aerodynamics, efficiency, etc. Anyone interested in the evolution of bicycles will find something worth reading here. Many better libraries have this book.

- Bicycle Metallurgy for the Cyclist by Douglas Hayduk addresses many common questions about the various metals used in building bicycles and components. It's not a how-to manual, but it is loaded with useful information and debunks many popular myths.

- The Proteus Framebuilding Handbook by Paul Proteus was a cult classic for many years, but has been out of print even longer than Talbot. A good guide to traditional framebuilding if you can find it.

- The

Custom Bicycle: Buying, Setting Up, and Riding the Quality Bicycle

A classic, if slightly dated, introduction to custom bicycle frames, published in the 1970s bicycle boom but still relevant to road bikes today. The book begins with an introduction to frame building techniques and tubing, then the majority of the book is devoted to profiles of recognized frame builders in Britain, France, Italy, and the U.S., discussing design philosophies and construction methods. Finally the book has close to 70 pages on setting up a bike, both fitting the rider and integrating the components -- all friction shifting, of course, so the discussion pays more attention to chain line than cable housing.

The book clearly shows its age in the laid back frame geometries, long chainstays and comfortable, rearward position of riders. Such old-fashioned designs may be out of favor with modern racers, but they are still wonderful for recreational, practical, and touring bikes.

At the time the book was written, many prominent frame builders did not use jigs, and some didn't even use torches: Mercian's brazers are cited as preferring bronze to silver brazing because "bronze flows nicely and works particularly well in the open hearth."

The many black and white photographs in the book provide fascinating glimpses of the insides of many renowned frame shops, glimpses that would make many shop teachers cringe. But take heart -- if the "Great Masters" could make world-class frames with hand files and open hearths, surely you can do as well with a jig and a torch!

- Bicycle Design: Towards the Perfect Machine by Mike Burrows is a technical look at many aspects of bicycle design, written by a bicycle designer and engineer at Giant Bicycles known for his work on carbon fiber, compact frames, and recumbent bicycles. Not a how-to manual by any means, but loaded with information that can help you decide what you want to do and what might be the better ways of doing it.

- How to Build Unicycles and Artistic Bicycles addresses some ideas you won't find in books about "serious" bikes. Ever want to build one of those bizzare parade bikes?

This page written by Josh Putnam. Please feel free to email questions, comments, corrections, suggestions, etc.

Josh Putnam's Home Page | Josh's Bike Page. | Josh's Framebuilding Page. | Josh's Photo Page.

© Joshua Putnam